QUALITY ALUZINC PRODUCTS

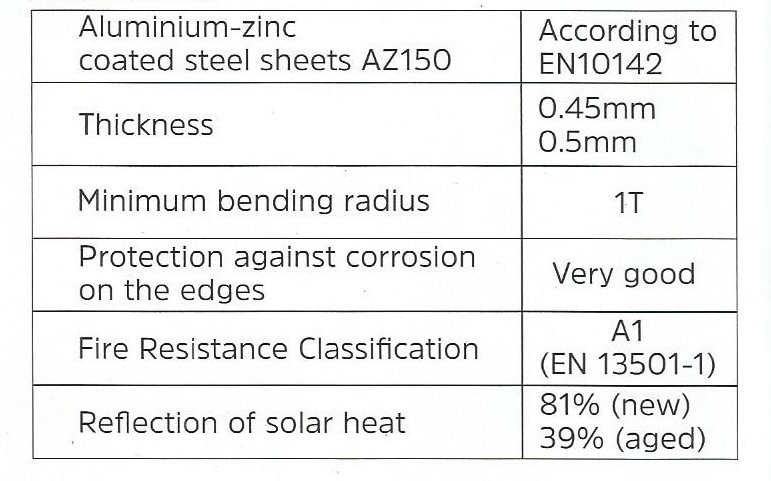

Aluminium Zinc AZ150 (30 years Warranty)

Product Description

The surface is initially glossy metal with a rose pattern but after some time it turns greyish, and eventually it becomes matt grey.

Appearance

The surface is initially glossy metal with a rose pattern but after some time it turns greyish, and eventually it becomes matt grey.

Trimming Edges

Normally, the trimmed edges do not need to be painted but in corrosive environments in which the trimmed edges are aesthetically prominent a protective paint is recommended to be applied.

Lifetime

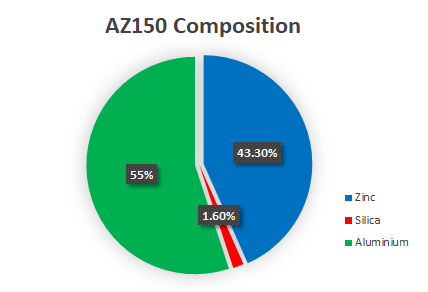

It is customary to separate between the aesthetic and technical lifetime. The aesthetic lifetime is a measure of the time it takes for the top coat to change to such an extent that the appearance no longer meets the requirements. The technical lifetime is the time it takes until the sheet no longer can protect the supporting constructions or foundations of the building. The layer of Alu-zinc has a thickness of approx. 20 μm (0.020 mm) per side for AZ150.

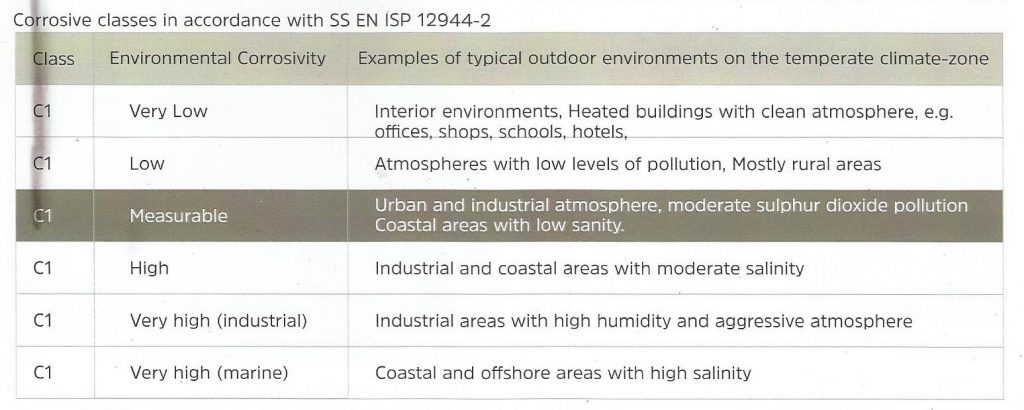

The corrosive speed, i.e. how much of the coating that disappears each year, is a maximum of 0.2 μm in a normal environment (C2) in which Alu-zinc is freely exposed. Due to corrosive and appearance related reasons, the following combinations should be avoided to prevent them from affecting the aesthetic and technical lifetime:

Alu-zinc in combination with copper, brass or lead can cause galvanic corrosion. Avoid drainage from constructions and roofs that contain these metals. In particularly aggressive environments, even stainless steel and nickel can increase the corrosive speed of Alu-zinc.

Alu-zinc in contact with high grade woods, damp wood or wood with waterproofing containing copper can cause black rust or corrosion.

Alu-zinc in combination with bitumen products without a UV stabiliser.

Alu-zinc in combination with wet concrete, cement and plastering that are very alkaline can cause discolouration or black rust.

Corrosion

Alu-zinc has an ability to repair itself which makes the material resistant to corrosion caused by scratches. The long lifetime is due to the fact that the aluminium-zinc coating provides the steel sheet with a double protection against corrosion. The first protection factor is the coating on the steel sheet that forms a passivating barrier against general corrosion. The other protection factor involves the formation of a galvanic element when the sheet is exposed to moisture (electrolyte), resulting in zinc ions flowing over and protecting the exposed steel against corrosion in scratches or trimmed edges.

Importance of AZ150

- Very Good Flexibility

- High Quality

- 100% Recyclable

- Corrosive Class C3

- Ability to repair itself.

Free Estimate

Request A Quote

Want us to work on a project for you? West Coast is just a click away from you. Request a free estimate for your building.

Environment

The long lifetime of Alu-Zinc, in comparison with for instance hot dip galvanized sheets, entails major environmental benefits. There is worldwide steel is produced for recycling steel that works well. Once steel is produced. It is part of a constant cycle as steel always recycle materials. Steel is always 100% recyclable, the metal layer does not pose any problems for remelting.